|

|

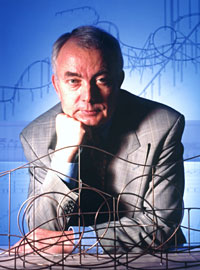

Josef Herzog is developing the Typhoon car

with support of CAD |

|

"There were just six months to design the first version

of Euro Fighter from scratch", Josef Herzog, engineer at

Gerstlauer, remembers. In spring of 2003 this ride was presented

to the public at BonBon Land, Denmark, and less than 12 months

later the second version will follow. Typhoon uses the same cars,

brakes and drives.

Calculations were done, hundreds of single component graphs made

using a computer aided, technical drawing program - in short CAD -

and suppliers searched. "We studied dozens of product

catalogs and had many talks with potential suppliers before we

found the right chain for our lift tower, for example", says

Siegfried Gerstlauer. For Gerstlauer Elektro GmbH

building a roller coaster is everyday business, for other

companies a very exceptional venture.

A roller coaster wants to be well thought through: Without

production drawings and a documentation of the calculations none

such ride can go into service. Neither can a strict coordination

be missing. So the first step of each project is creating a digest

of the schedule, combining causal contexts and the temporal

workflow: So the track can only be produced as soon as all the

calculations are finished. And for designing the layout a defined

interface between the car and the track has to be agreed on: The

engineers have to clarify which elements and features can be

negotiated by the cars. "Depending on the workload we assign

tasks to external engineering offices", Siegfried

Gerstlauer explains. Regarding the output of six coasters for

the 2004 season - a new record high in the history of the company

- the tasks have to be well allocated to the 30 employees.

|

|

At the beginning of the design process stands the basic idea

regarding the layout like it was described in the last issue of

this series. Afterwards the design of the car is made, including

construction and engineering of the chassis. Service strength

certificates play a leading role when designing the components.

There is a mathematical stability proof to be adduced for each

component before production can start. The adequate state of the

art is outlined in standards like the Deutsche Industrie Norm

(DIN, German Industry Standard) or the European Norm (EN).

The universal tool for the engineer is the CAD that completely

ruled out the classic drawing board and the tusche box: Changes

can be done much faster using the computer, standard parts like

screws, springs and nuts can be taken from libraries and bills of

material can be derived directly from the drawing. A looping

coaster like Typhoon consists of thousands of single

parts - a really complex "puzzle" making high demands on

the designer. There is no apprenticeship or degree for roller

coaster engineers, this job rather is a mix of interdisciplinary

competencies regarding steel construction, mechanical and

electrical engineering. "Today you work on the cars and

tomorrow's task is to design the sole", Josef Herzog outlines

his areas of responsibility.

After completing the specification of the car the design of the

layout begins. In a first step this happens only regarding the

forces affecting the passengers, being extended to the steel

construction itself in later stages of the process. The engineers

aim to turn the basic idea into a layout that obeys the state of

the art. Stability proofs have to be adduced, safety devices

constructed and components dimensioned and developed. A network of

steel pylons keeps the coaster together and draws the highly

dynamic loads out to the earth. Adequate instructions for the

production can be derived from the mathematical calculations. A

roller coaster is supposed to push the limits and to

comply with the safety standards at the same time. Safety is put

in capital letters when building amusement rides, so the

manufacturers cooperate with TÜV from early on,

starting at the first development phases. |

|

|

Overview Design - From sktech to final

production datas |

|

The layout is the geometrical sketch of

the track. It shows the exact sequence of the ups and

downs and the inversions. The graphics consists of a

ground view and an unwind of the track. |

|

|

Ground view: Track and heartline are

shown - Maximize with left click |

|

The ground view shows the track layout by

aerial view. The unwind of track shows the track

unrolled in a plain view. Especially the height

progression is visible. Also technical information

(inclination, distance of columns, ...) are given.

|

|

|

Unwind of track - Maximize with left

click |

|

The 3D-layout is a combination of ground

view and the unwind of track. It is used to visualize

the track layout and does not consist of technical

information. |

|

|

3D-layout - Maximize with left click |

|

The layout is part of the design process

and the cinematic/kinetic result of the track

calculation and configuration. This field of activity

- called dynamics - considers speed, accecerations and

forces (e.g. created by acceleration of train).

Stengel engineering office makes the calculations in

relation to the riding people, the car and the track

to appoint the maximum forces. This calculation is the

basis for the force compatibility for the riding

people and the design of steel structure. |

|

Nex to layout and dynamics, the static is

the third sub area of roller coaster design. The

column constuction and the steel sole is designed to

absorb the dynamic and static forces - sometimes

multiple tons - and the self-weight of the steel

structure. |

|

|

|

|

|

Werner Stengel |

|

The efforts regarding safety are shared by the Stengel

engineering office in its history of almost 40 years: The graduate

civil engineer Werner Stengel is called "Master of

horror" and was involved in around 600 roller coasters

worldwide. The field of activity of his team, consisting of ten

employees, comprises the exact design of the layout on the basis

of dynamics calculations, includes statics and the computation of

the foundation loads. Gerstlauer, too, avails the services

of the Munich-based engineering office that has worked for all

renowned coaster manufacturers.

The starting point of all considerations regarding Typhoon's

layout was the rough design of the sole and the unwind of the

track, two points the wire model for the presentation at the trade

shows was based on. "Our vision is clearly defined by giving

a layout to the Stengel engineering office", Siegfried

Gerstlauer tells us. "In addition, there were pilot

surveys regarding the car prior to the allocation of the project,

determining the maximum forces and the minimum track radii."

A clear interface definition fixes the cooperation from the

beginning: "The further design of the cars as well as the

layout have to adapt to that", Siegfried Gerstlauer

comments.

Engineering office Stengel optimizes the track at the

computer, using elaborate numerical algorithms to keep the forces

on the passengers below a limit. Every change in direction causes

an acceleration ,

and every coaster has lots of them: Bends, drops and inversions

are analyzed to keep them ridable. Stengel can count on an

extensive amount of experience. Keywords like heartline ,

and every coaster has lots of them: Bends, drops and inversions

are analyzed to keep them ridable. Stengel can count on an

extensive amount of experience. Keywords like heartline and spline

curves

and spline

curves play a lead role when finding the ideal position of the track in

space.

play a lead role when finding the ideal position of the track in

space.

The amount of data is so huge that it can only be handled by

self-made software - The calculations for Typhoon would need

57.000 pieces paper. "Without the use of computers roller

coasters couldn't be designed nowadays", Andreas Wild

of the Stengel engineering office tells us. "Especially

the development and implementation of our program for spline

curves enabled us to design coasters running ultimately smooth and

to give precise instructions for the production to the

manufacturer. Regarding the very short development times these

days we have to use highly modern tools to calculate the rides."

More than 3000 hours of work have been done at the Stengel

engineering office just for Typhoon. Here, too, modern

3D-CAD systems help the engineer to sound the limits of biodynamic

tolerances of the passengers. A simulation of the coaster can be

done based on the CAD data, and so the forces and the dynamic

behaviour can be determined way before a prototype has been built.

The roller coaster is virtually assembled early in the design

phase to test functional relations and mechanisms.

The production data (CAD files and other lists) represented by

3D coordinates and production directives for track, supports and

sole are sent to the manufacturer electronically. "In

principle we can start producing directly from the data we get

from the Stengel office. But mostly we adapt the data to

the local factors at the track manufacturer's site", Siegfried

Gerstlauer explains the process. Track production happens,

depending on workload, "in house" or is passed to a

third party. After five months Typhoon was designed to the

last detail, so the steel construction as well as the production

of the cars could start in summer of 2003.

Typhoon - a roller coaster emerges will be continued. Read

and see in our next issue how the single components of the looping

coaster Typhoon have been produced at the Gerstlauer facility.

Many thanks to Gerstlauer Elektro GmbH and Stengel GmbH for

the friendly support on realizing this article. The copyright for

the pictures belongs to the photographers and the Gerstlauer

Elektro GmbH, Stengel GmbH and Andreas Fechner, respectively.

Publishing, distribution and copying without written permission is

strictly forbidden. |